Cost Effective Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Cost Effective Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Blog Article

Opening the Keys to Reliable Lift Services: Specialist Insights Disclosed

In the world of lift fixing and maintenance, uncovering the techniques that lead to effective and effective solution is akin to deciphering a complicated puzzle. As we begin on this journey to demystify the keys behind streamlined lift fixings, a world of opportunities arises, guaranteeing a future where downtime is decreased, safety is prioritized, and operational quality becomes the norm.

Usual Lift Repair Work Challenges

An additional widespread difficulty in lift repairs is the lack of appropriate maintenance records. Without accurate upkeep documents, repair work specialists might battle to identify concerns properly or prepare for potential troubles. This can lead to longer repair service times and enhanced costs as technicians function to troubleshoot issues without historic information to direct them.

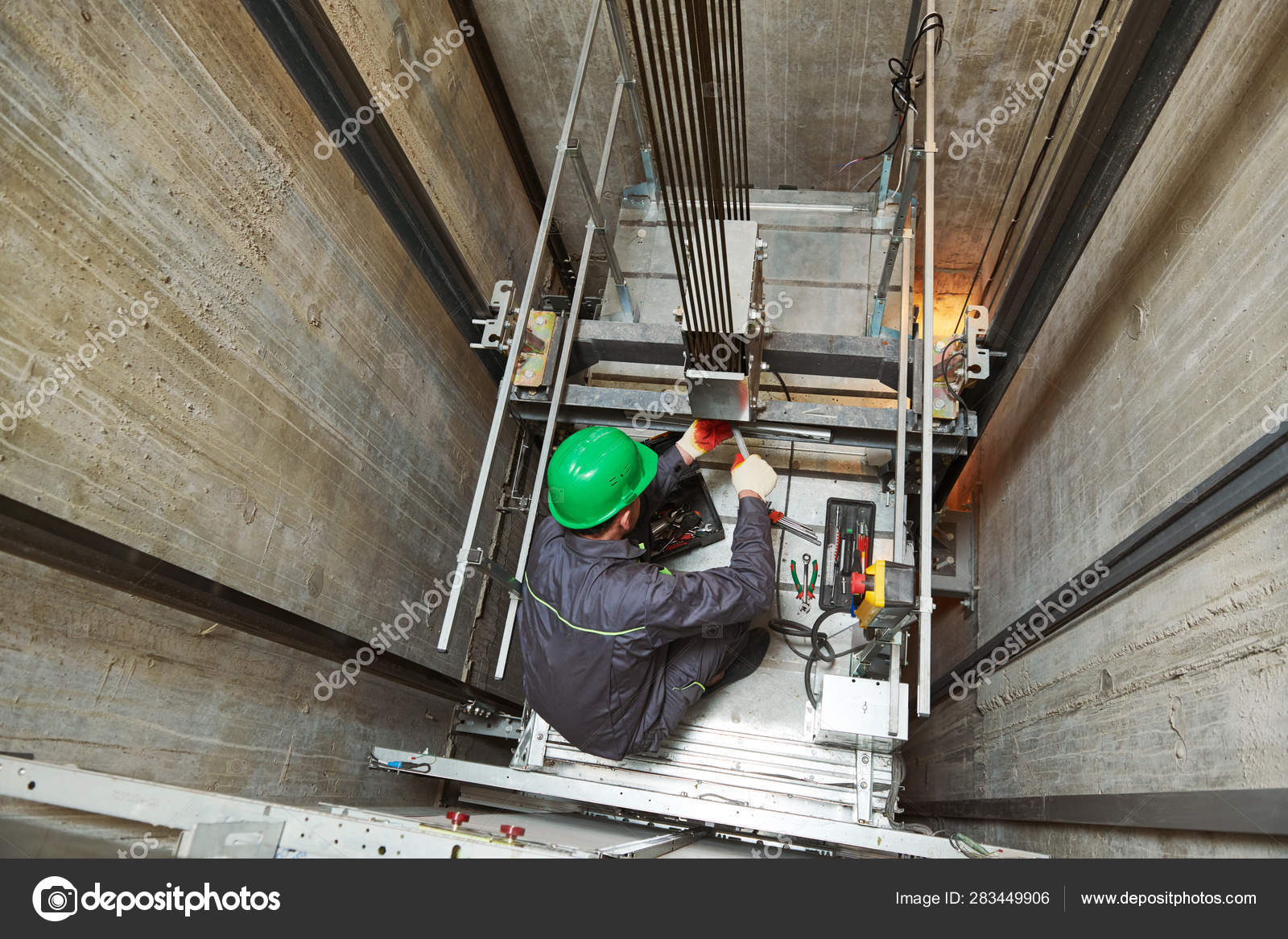

Furthermore, accessibility concerns within lift shafts can present substantial obstacles during repairs. Minimal area, awkward angles, and intricate equipment can make it tough for specialists to get to the needed components for repair, prolonging the general repair work procedure - Lift Maintenance Repair. By attending to these common obstacles proactively, lift repair work specialists can improve functional effectiveness and ensure the smooth functioning of upright transportation systems

Proactive Upkeep Techniques

Executing proactive maintenance approaches is critical for making certain the durability and optimum performance of lift systems. By embracing a positive approach to upkeep, building managers and lift maintenance groups can attend to possible issues before they rise into expensive fixings or downtime. One reliable approach is to develop a regular maintenance routine that consists of comprehensive examinations, lubrication of relocating components, and testing of safety functions.

Additionally, buying training programs for upkeep personnel can improve their abilities in determining possible concerns and executing preventive upkeep jobs effectively - Lift Maintenance Repair. By empowering upkeep teams with the expertise and devices required to proactively preserve lift systems, building owners can minimize disruptions, extend the lifespan of their lifts, and guarantee a reputable and risk-free vertical transportation experience for occupants

Repairing Techniques

Reliable fixing strategies are necessary for promptly determining and dealing with problems with lift systems to minimize downtime and make certain optimal efficiency. One effective method is to begin with a comprehensive aesthetic inspection of the lift elements, examining for any type of noticeable indicators of wear, damage, or misalignment.

Enhancing Repair Abilities

Enhancing effectiveness in lift system repair work is a basic facet of making sure optimum functionality and decreasing operational disturbances. Lift technicians need to consistently function on developing their fixing skills to Continued satisfy the needs of modern-day lift systems.

Additionally, remaining upgraded with the most up to date advancements in lift innovation is vital for technicians wanting to improve their fixing abilities. This involves actively looking for details concerning brand-new components, software updates, and maintenance methods to successfully detect and fix issues. By investing time and effort into constant discovering and functional experience, lift professionals can dramatically increase their repair work expertises and add to the reliable performance of lift systems.

Boosting Upkeep Requirements

Boosting maintenance standards in lift systems is paramount for ensuring prolonged functional performance and safety and security. Routine maintenance not just enhances the efficiency of lift systems however likewise reduces the risk of unexpected breakdowns and makes certain the safety of users. By sticking to strict maintenance methods, lift proprietors and drivers can considerably decrease the likelihood of pricey fixings and downtime.

Carrying out an extensive maintenance timetable that includes regular evaluations, lubrication of moving components, and positive replacement of used components is crucial. Making use of sophisticated technologies like IoT sensing units and predictive upkeep software application can help in checking the lift's condition in real-time, enabling prompt interventions prior to issues rise. Furthermore, providing constant training for upkeep personnel on the most up to date market standards and finest practices is necessary for supporting upkeep excellence.

Furthermore, promoting a society of accountability and interest to detail amongst upkeep teams can additionally boost maintenance criteria. Encouraging open communication channels for reporting and resolving maintenance worries without delay can help in maintaining a high degree of lift system reliability. Ultimately, by focusing on and boosting maintenance standards, lift systems can operate effectively and securely for an extensive duration.

Verdict

In conclusion, efficient lift repair work need positive maintenance approaches, fixing strategies, and boosted fixing abilities. By addressing common challenges and elevating maintenance requirements, maintenance professionals can effectively ensure the smooth procedure of lifts - Lift Maintenance Repair. Applying these professional insights can lead to improved performance, lowered downtime, and boosted security for both travelers and equipment

In the world of lift fixing and maintenance, discovering the methods that lead to reliable and effective service is akin to deciphering an intricate challenge.One more prevalent obstacle in lift repair services is the lack of correct maintenance records. By taking on a positive approach to maintenance, building supervisors and lift maintenance groups can deal with potential problems before they rise Going Here into pricey repairs or downtime.In verdict, effective lift fixings need proactive upkeep strategies, repairing techniques, and boosted repair service skills. By boosting and addressing typical challenges maintenance criteria, maintenance specialists can effectively make sure the smooth operation of lifts.

Report this page